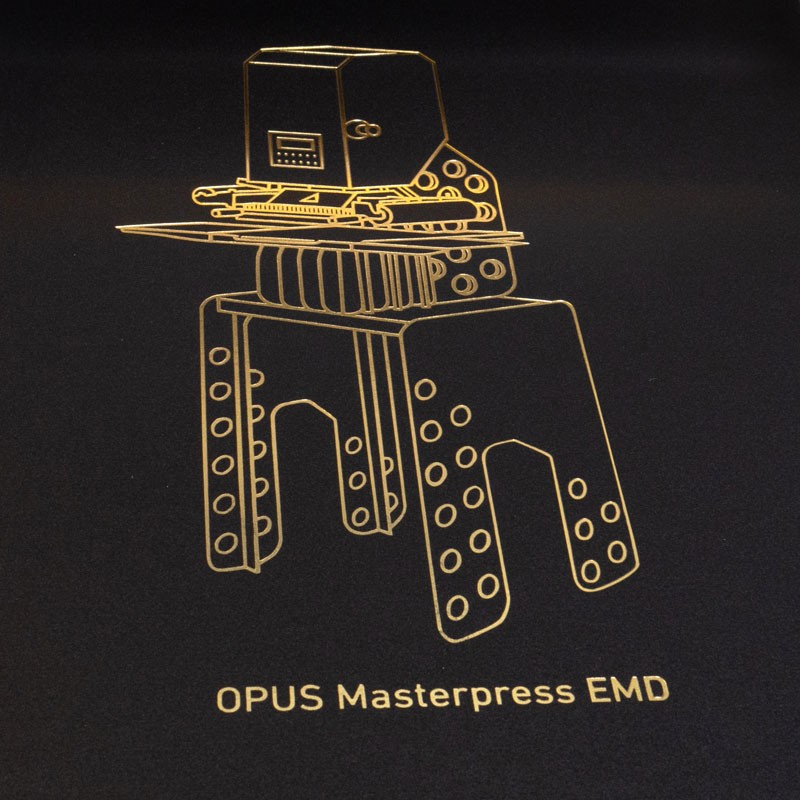

Professional electric hot print stamping machine

Electric hot print stamping machine - OPUS Masterpress EMD+

- Catalogue number: 415519

Professional electric hot print stamping machine

Electric hot print stamping machine - OPUS Masterpress EMD+

0 (0)

- Catalogue number: 415519

OPUS Masterpress EMD+

Masterpress EMD+ professional electric machine designed for gilding, stamping and punching. Gilding (silver plating) is made with the use of hot print stamping method (also called thermo-printing, hot-printing) - with the use of foils and convex matrices. Thanks to its excellent results, it is ideal for service outlets, printing houses, producers of books, photo-books, albums, cardboard and leather goods and public administration.

The design

The well-thought-out, robust metal construction of the EMD Masterpress guarantees stability, safety and repeatability of work. Powder coating provides resistance to corrosion, high temperatures and mechanical damage. The advanced press construction based on an eccentric mechanism enables pressure up to 7 tons.

Programming enhacements

A microprocessor-based PID programmer is responsible for all operating parameters. The user can set the temperature, the stamping force, the distance between the matrix and the material, the stamping time, the daily counter (counting mode or countdown) and the amount of rewound film. In addition, the 10 most frequently used settings can be programmed. The operating status of the machine is continuously displayed for the operator.

Convience of use

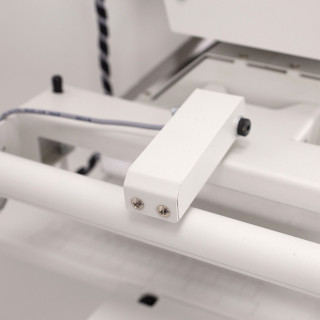

The machine includes an extendable work table with millimetre scale, metal stops for accurate and repeatable setting of the material. The work table can be accurately adjusted by means of as many as 12 screws. Additional side tables and front table are useful when working with larger materials.

Materials for hot print stamping

The machine is designed to work with paper, cardboard and veneer-covered paper covers. It is also possible to work on non-standard materials, e.g. materials covered with leather or leather-like materials, but it requires individual tests and selection of settings. You can gild covers, business cards, folders, invitations, cards, labels, envelopes, etc.

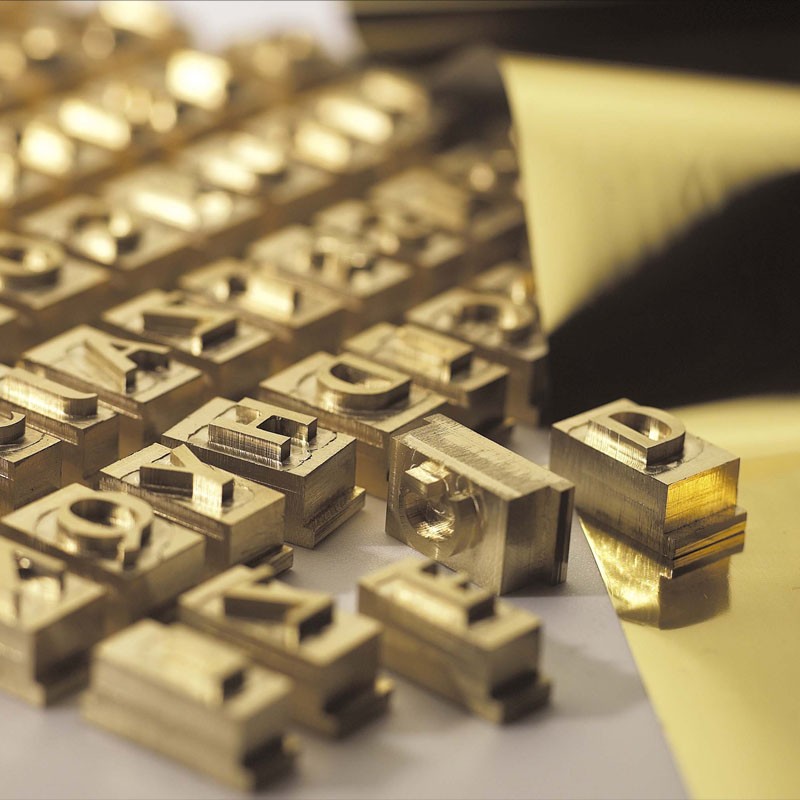

Matrices / Fonts / Frames / Hot-stamping foils

The maximum matrix format that can be used is 218 × 308 mm. The OPUS range includes individual matrices in various sizes made specifically for the customer, fonts available in different formats, typefaces and languages, frames that allow any text layout, and multicoloured foils in sheets and rolls. It is also possible to combine an individual matrix with a text created from ready fonts. Foils for gilding and glossing are available in various colours.

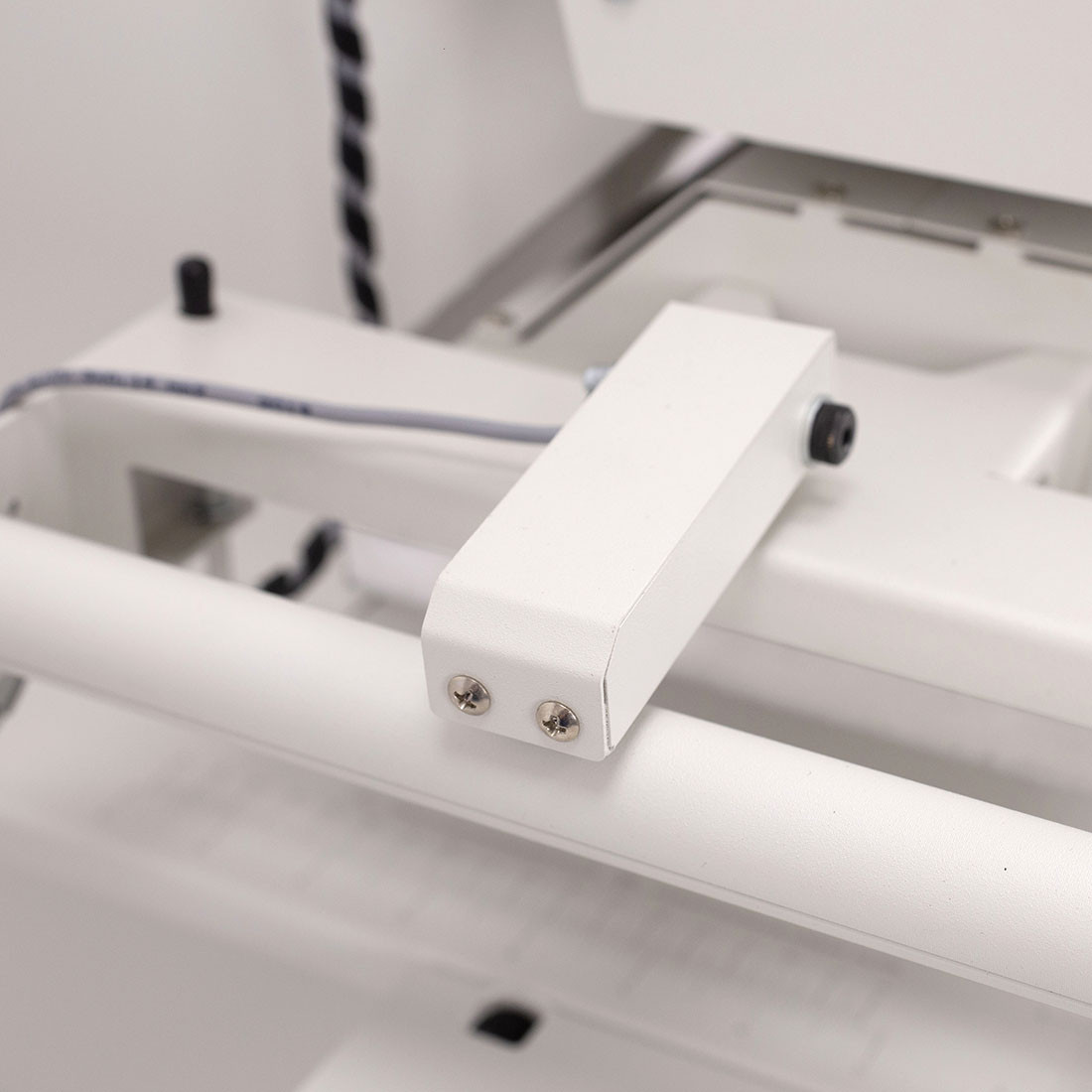

Automatic advance of hot print stamping film

The use of foils on a roll significantly speeds up work, especially when we have a series of covers to be gilded. The well-thought-out design allows for central positioning of the most popular foils 180, 210 and 230 mm in relation to the die. Additionally, the applied counter measures exactly the amount of foil that has been programmed and a special brake ensures that it is properly stretched. This allows for economical working especially when using smaller matrices.

User safety

For reasons of operator safety, the machine requires ambidextrous operation. Releasing one of the two buttons during the downward movement of the head causes immediate stopping of the pressing / punching process. Additionally, Masterpress EMD+ is equipped with an emergency stop and the possibility of locking the device with a key. Safety is also confirmed by the CE certificate.

Transport / Assembly

The device is supplied on a wooden pallet, which ensures easy transport, e.g. by means of a forklift or pallet truck. The set includes comfortable handles, which significantly improve the comfort and safety of assembly of the device.

Key features

- adjustable pressure up to 7 tonnes

- digital setting of all operating parameters

- additional worktop adjustment

- pull-out working table with side tables

- stable construction

- wide range of accessories

- safety of use

- repeatability of gilding / stamping / punching

- single-phase power supply

Advantages over OPUS Masterpress EMD:

- increased rigidity of the body by using two full ribs

- extended stand for added stability

- increase in pressing force to 7 tons

- will speed up the pressing cycle by over a dozen percent

- Improved force repeatability by modernizing the main motor controller

- unified frame system compatible with Mastrpress 02 and Goldpress 5 devices

- faster assembly of the device thanks to the table regulators factory-installed in the body of the device, no need to reassemble the reinforcing beam, factory-installed transport handles

- new single-line O.Frame Long

- O.GOLDCHANNEL BASE MP01/MPEMD/MPEMD+ and O.GOLDCHANNEL BASE MP01/MPEMD/MPEMD+ LONG remain compatible with the device

Specification

| Gildin type | matrix |

|---|---|

| Glossing | hot print stamping and embossing |

| Brand | OPUS |

| Maximum matrix size | 200 x 300 mm |

| Temperature regulation range | 30 - 190°C |

| Maximum pressure | 7000 N |

| Force pressing adjustment | yes |

| LCD display | yes |

| Stamps couter | yes |

| Automatic film rewinding | yes |

| Power supply | 220 - 240 V, 50 / 60 Hz |

| Maximum power consumption | 2000 W |

| Rated power | 1500 W |

| Net weight | 128 kg |

| Gross weight | 206 kg |

| Stand net weight | 40 kg |

| Height | 1619 mm |

| Width | 650 mm |

| Depth | 600 mm |

| Device warranty | 2 years |

Downloads

-

User guide

Format: .PDF, size: 5.49 MB

-

Data sheet

Format: .PDF